Component rebuild and repair software

Digital task instructions for component rebuilds

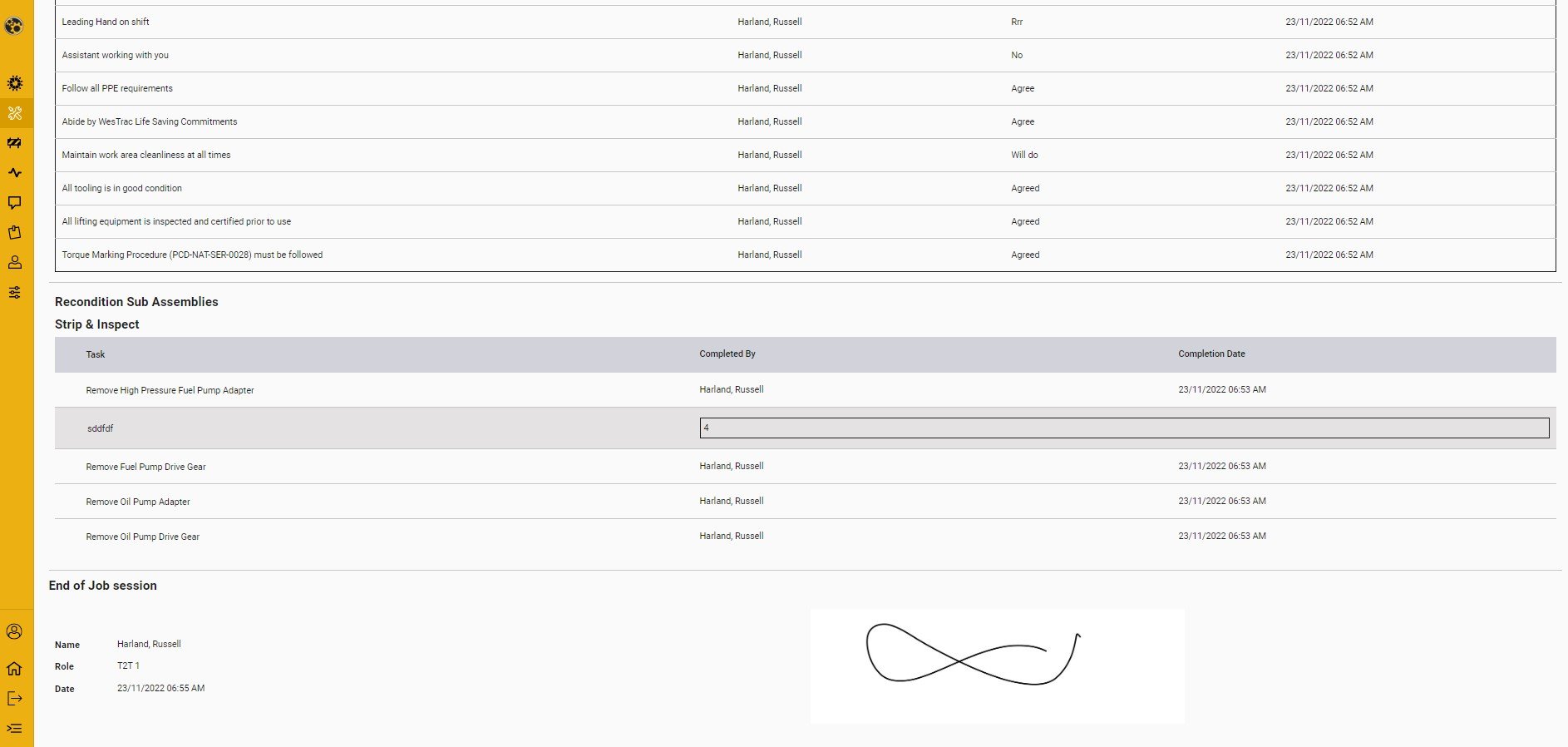

ComponentStatus helps you share complex work instructions for task-based processes simply and electronically. Each step clearly defines what the task is and how to do it, which trains the user on how to carry out a rebuild or repair safely and efficiently.

Use digital work instructions to improve any task-based process, no matter how complex or simple

There are some common issues with typical paper-based task instructions when it comes to component rebuilds and repairs.

Do any of these sound familiar?

- Time wasted due to slow performing and reporting processes

- Paper-based systems that require constant document rehandling

- Limited procedures, specifications, or reusability guidelines

- Inexperienced workers assigned to roles with no prior preparation

- Lack of awareness of potential risks involved

- Management is often unaware of where time is actually being spent

- No efficient way to track the parts needed for the job

What if there was a better way to simplify instructions for rebuilds and repairs that solves all these issues?

ComponentStatus is that solution.

How ComponentStatus can help your component rebuild center

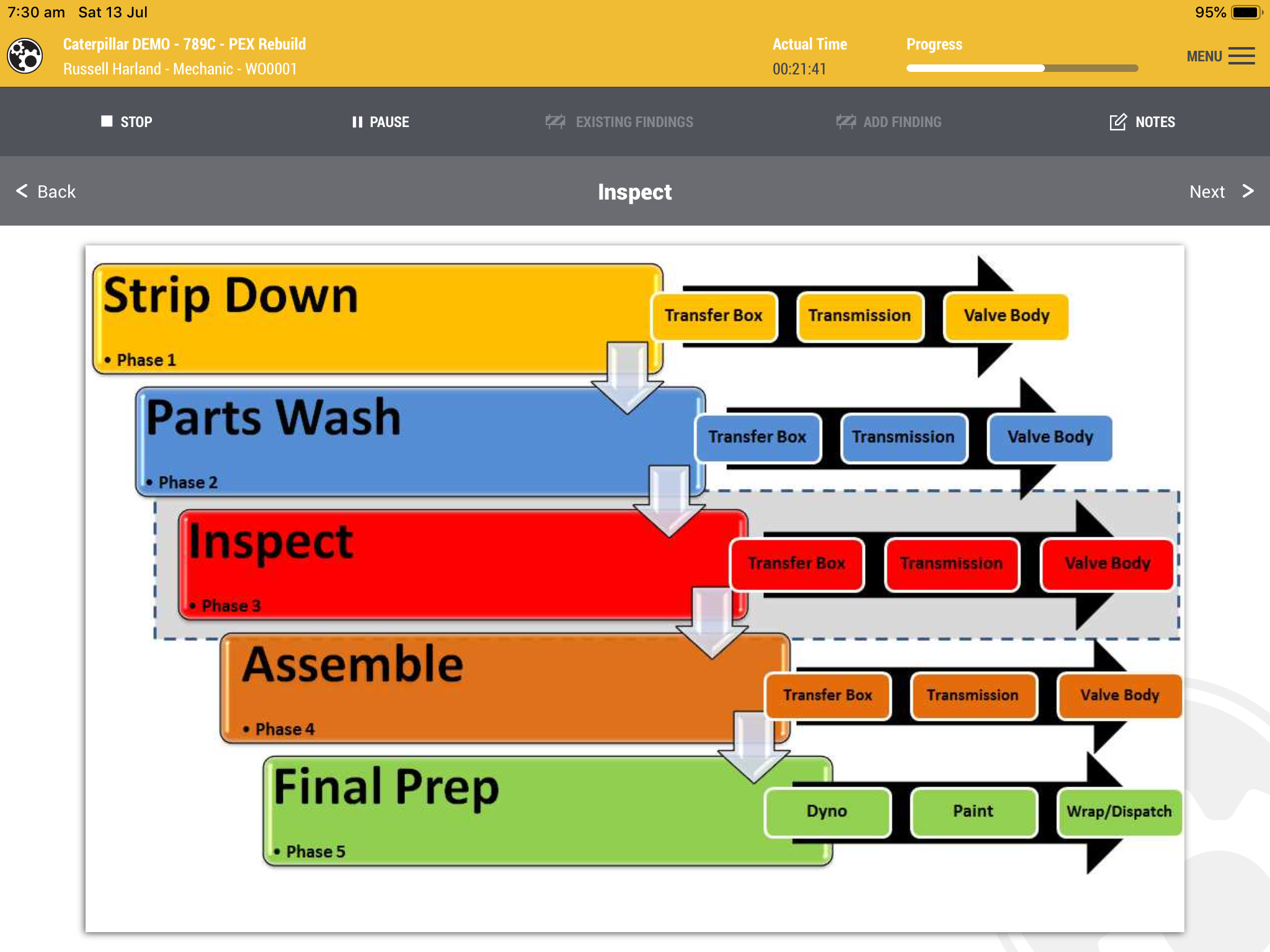

We offer companies a mobility-based software option that adapts complex strip down and assembly processes and procedures into easy-to-read and simple-to-follow structured task instructions.

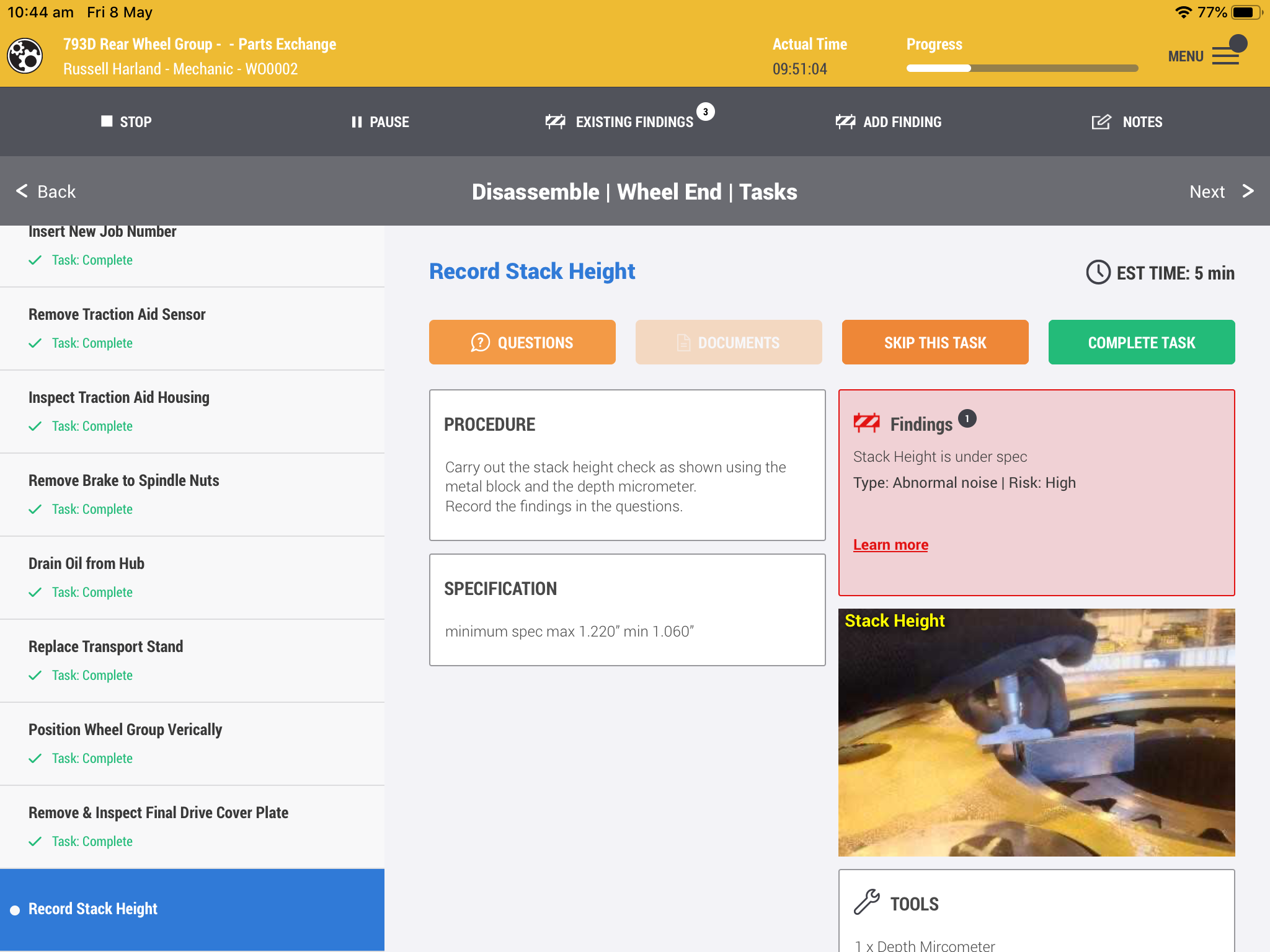

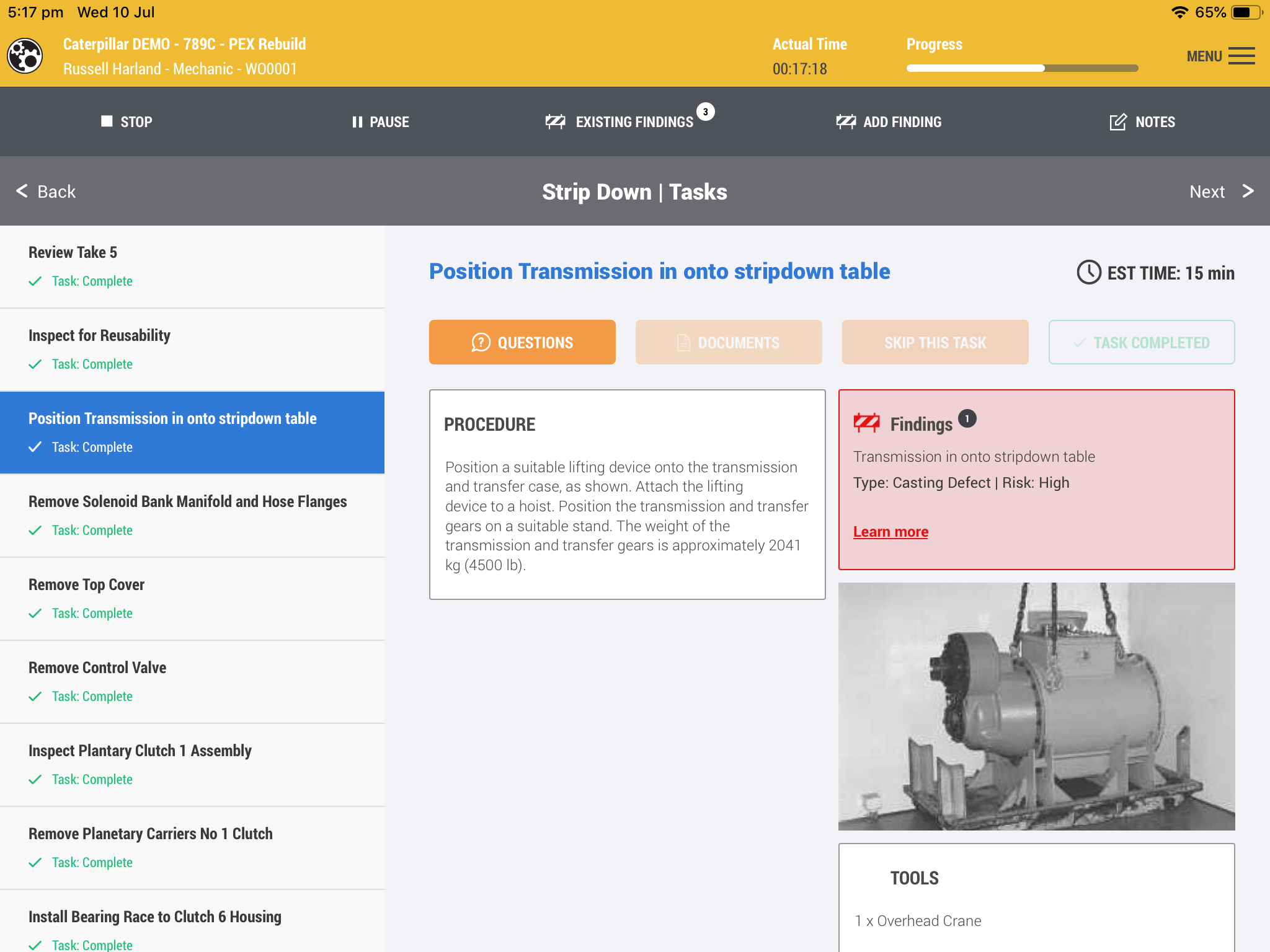

ComponentStatus electronically sets out for the rebuild technician what needs to be done, in what order, and how. It also details the specifications, and what’s required in the way of tools, parts, lubricant, and permits, so nothing is missed.

Images, videos and PDFs can also be used to support the steps of each process. And the system clearly identifies any risks involved and when contamination control needs to be applied.

As a result, ComponentStatus is an advanced digital tool for creating a method to perform rebuilds safely and effectively.

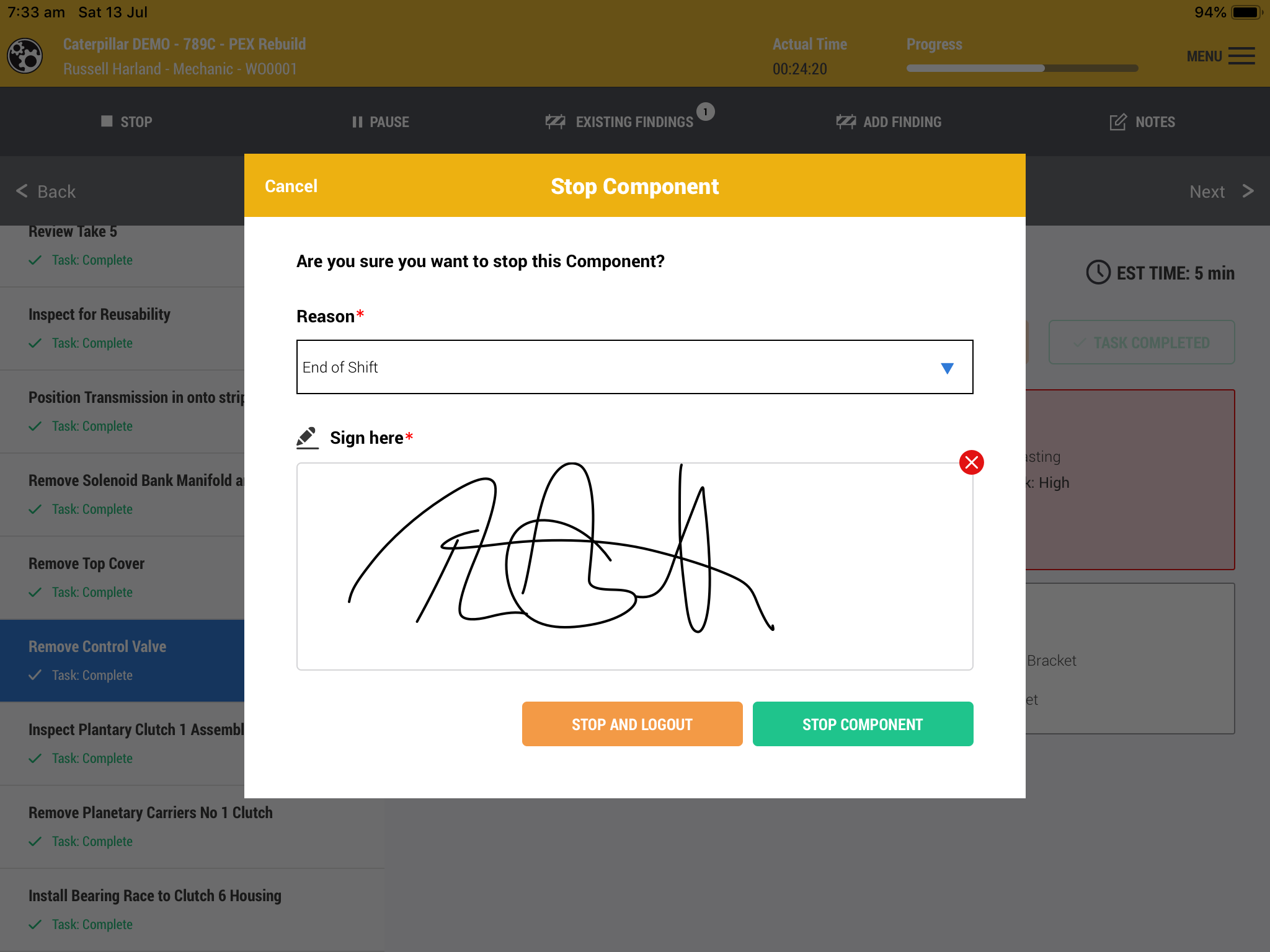

Now available on iPad

Digital work instructions shared simply

But it’s much more than just digital task instructions.

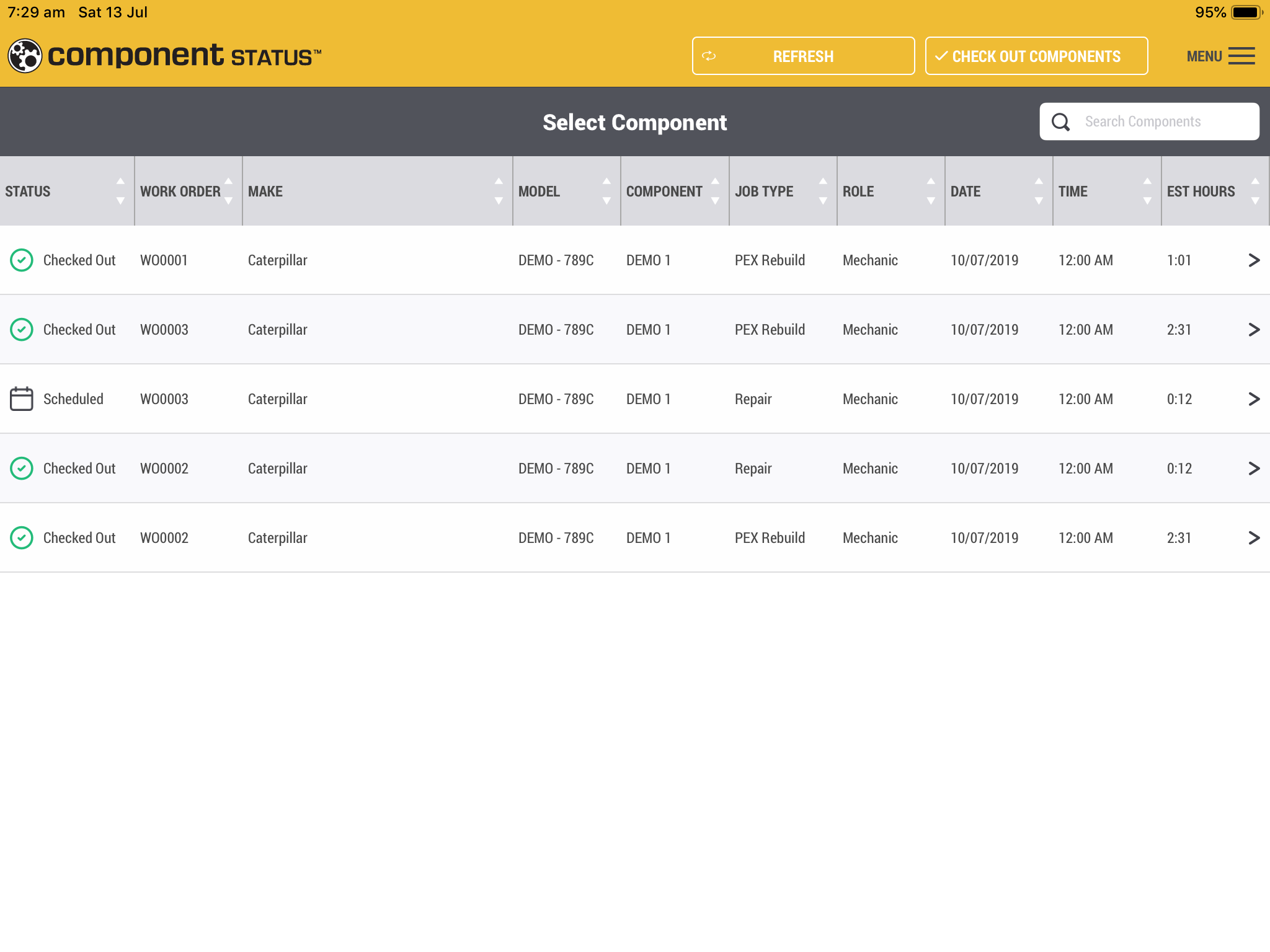

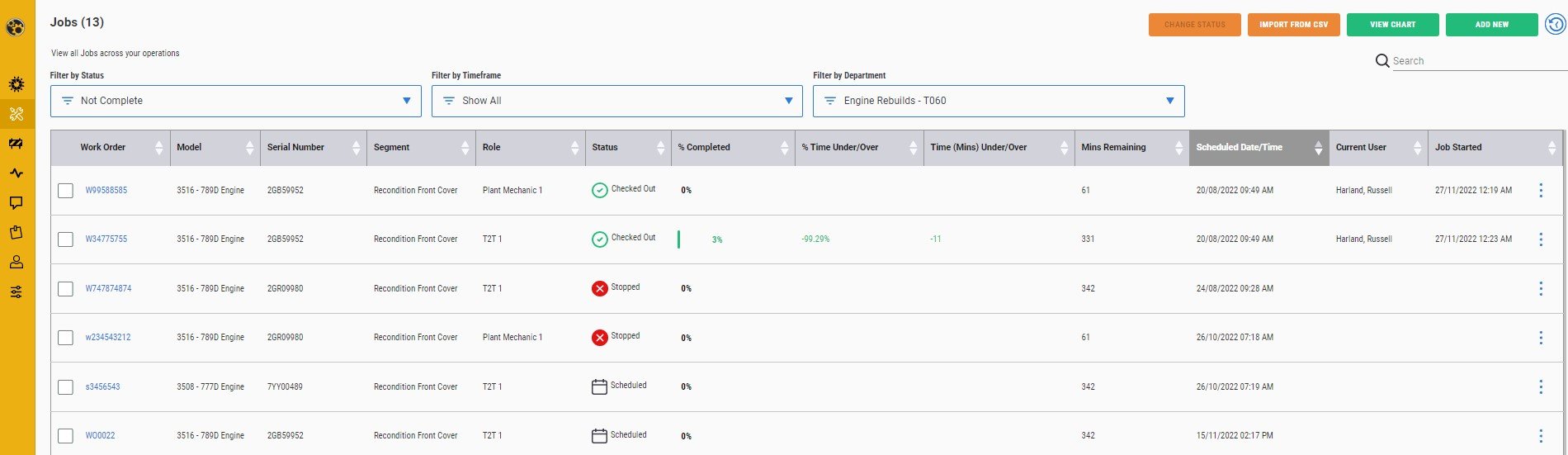

Job control at all levels of the business is very important to any component rebuild center. ComponentStatus provides you with a clear view of the status of all the work in progress. Who’s on the job, where they are up to, what impacts they have had and how much time is remaining. Additionally, ComponentStatus can show the condition of the component as it passes through the rebuild process. Any additional parts required can be captured against the task and job which means you can view some amazing analytics over the history of the component make and model.

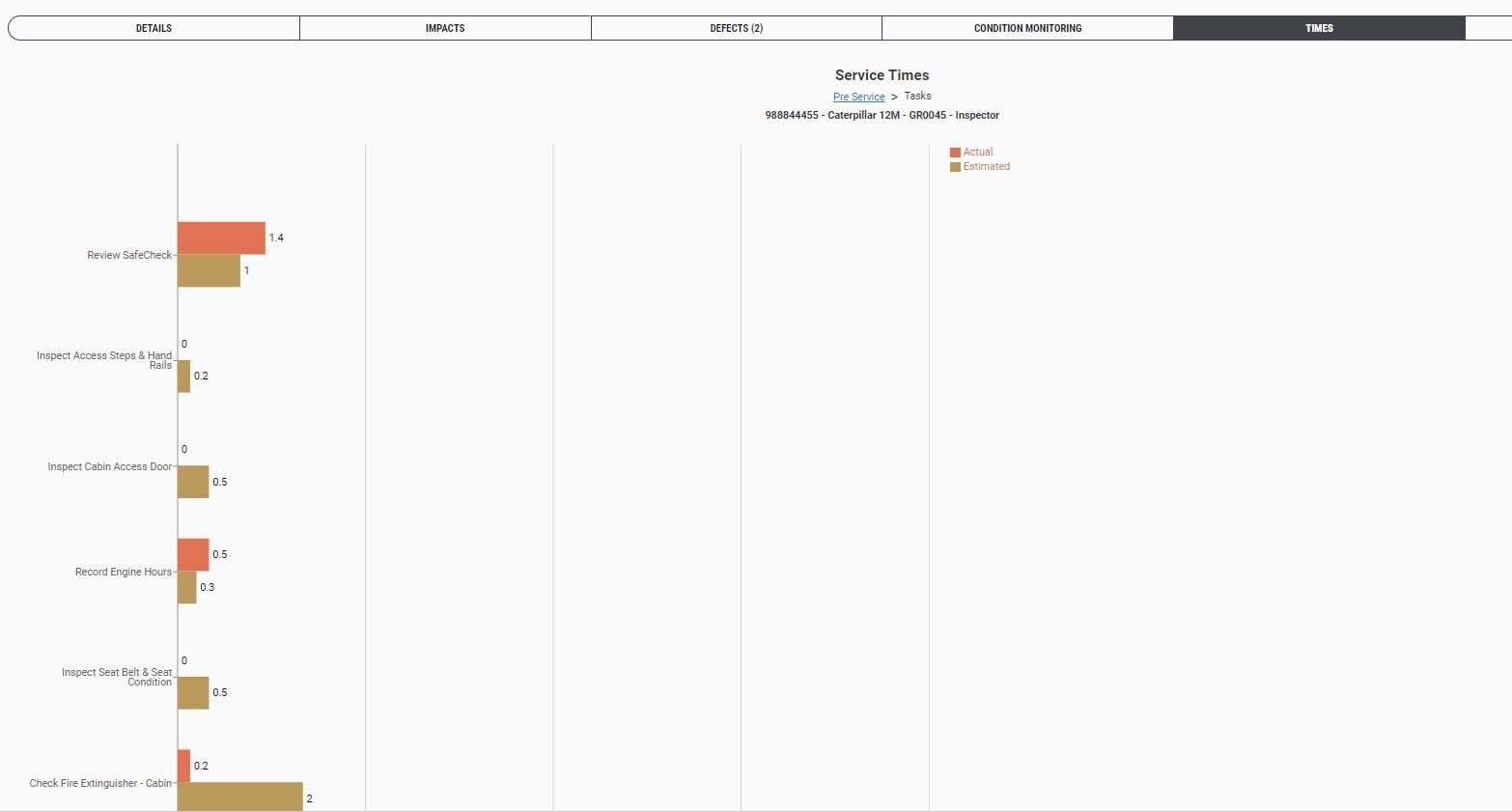

Job time line can be viewed along with actual vs estimated times against the complete job to the actual task.

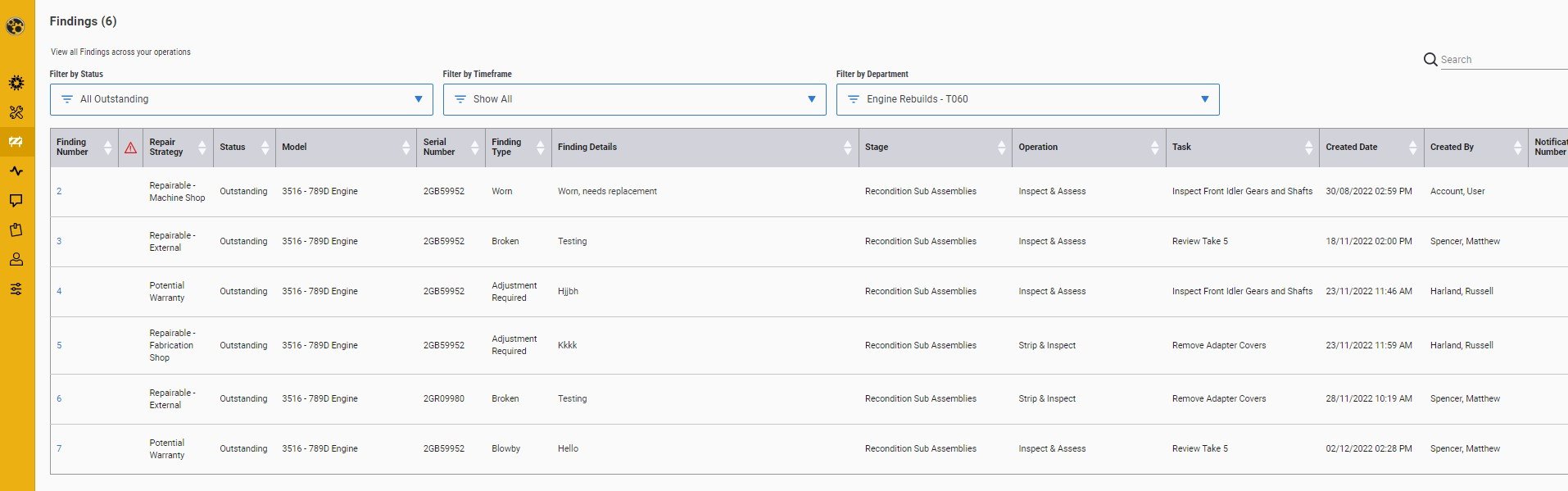

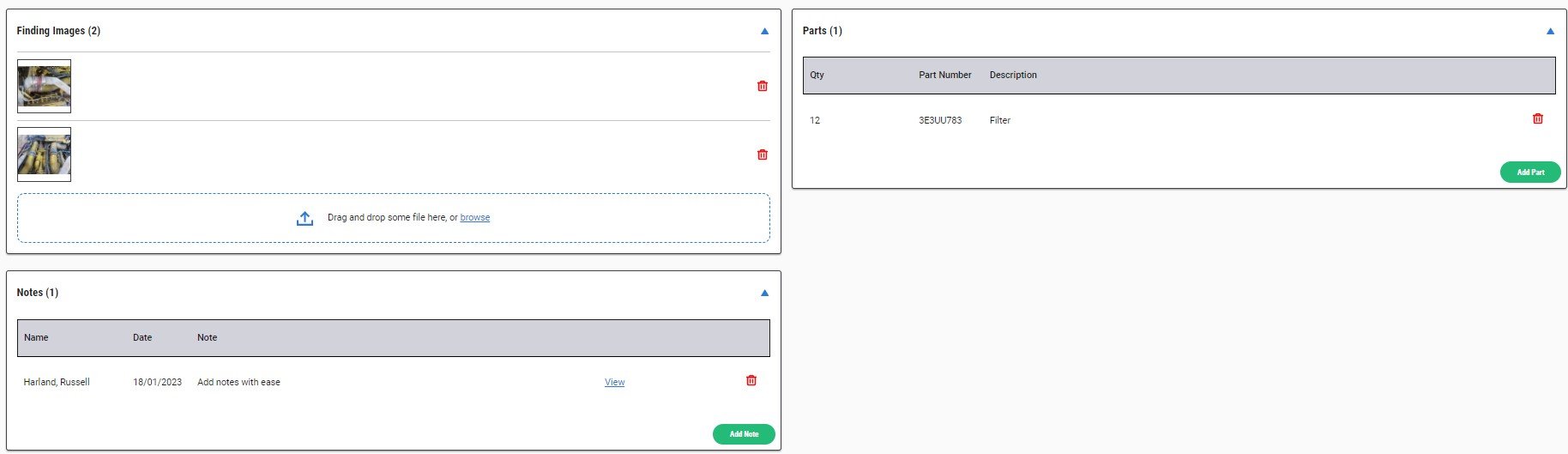

If a rebuild technician spots an issue with a component, it can be recorded electronically, risk-rated for future rectification priority, and images of the finding can be captured.

This means any previously reported or outstanding findings can easily be viewed, edited, and the status of the component updated.

Plus, technical questions are used as prompts to determine the actual condition of the component. Any values that fall outside the min/max range automatically trigger a reporting process for the issue.

ComponentStatus enables rebuild technicians to perform their tasks to the standard expected by your company; safely, efficiently, and with purpose and value.

Other solutions in our Status suite

Follow structured and practical safety audits and inspections using mobility-based solutions.

SafetyStatus allows you to remove generic paper-based checklists that slow down your operation. And with a focus on safe and efficient processes, the data is easier to collect, analyse, and make decisions on.

Simplify the instructions of your mobile equipment in line with your standards and expectations.

EquipmentStatus is designed to support equipment condition compliance. It’s ideally suited for rental equipment return inspections and release compliance, or MDG15 equipment inspections and audits.

EnviroStatus

Collect in-field data to monitor environmental condition and compliance requirements.

EnviroStatus helps your team easily collect and analyse critical values and condition of the environmental situation in near real-time. Ideal for any type of environmental condition audit or inspection.