When was the last time you looked into what’s happening on the floor in your workshop?

Do you know where the frustrations lie or what might be causing delays on the job?

The truth is, not many supervisors or managers know what the real issues are - let alone how to fix them - because they simply don't have the information.

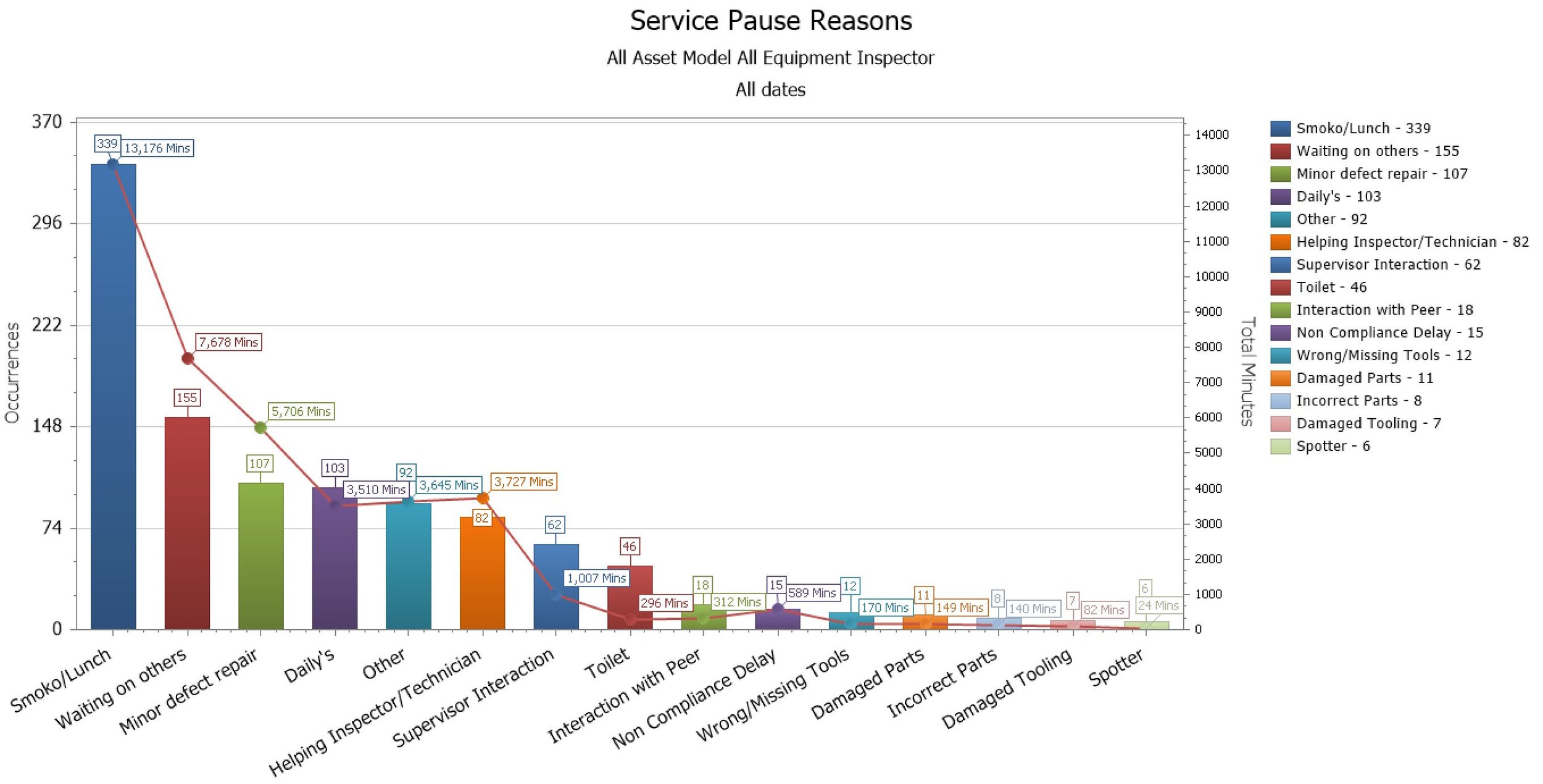

Workers are pulled off the job at random and for any number of reasons.

Perhaps another peer needs some help. Or it turns out they were supplied with the wrong part and need to switch it for the right one.

But what if you were able to see how many times your workers are pulled off the job.

What if you could measure the time impact of these interruptions and the effect they have on your ability to manage your fleet or plant?

Our two maintenance software options - ZoneMaintenance and RouteMaintenance - both provide this exact feature.

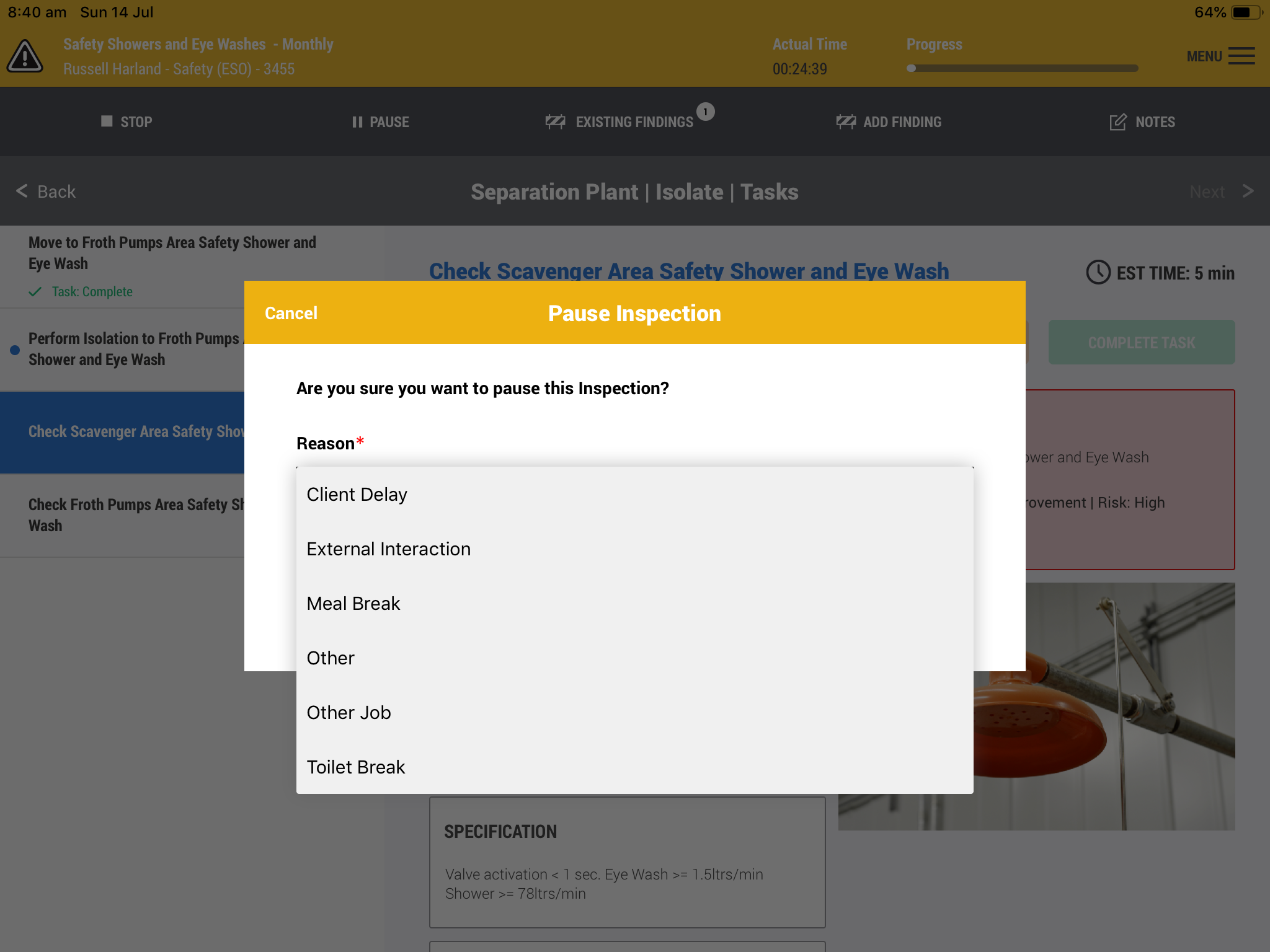

Workers can demonstrate these impacts by pausing the job.

Each task and job has a pre-set estimated timeframe, so when an interruption occurs the job can be paused. This means there’s a more accurate record of the timing of the actual job.

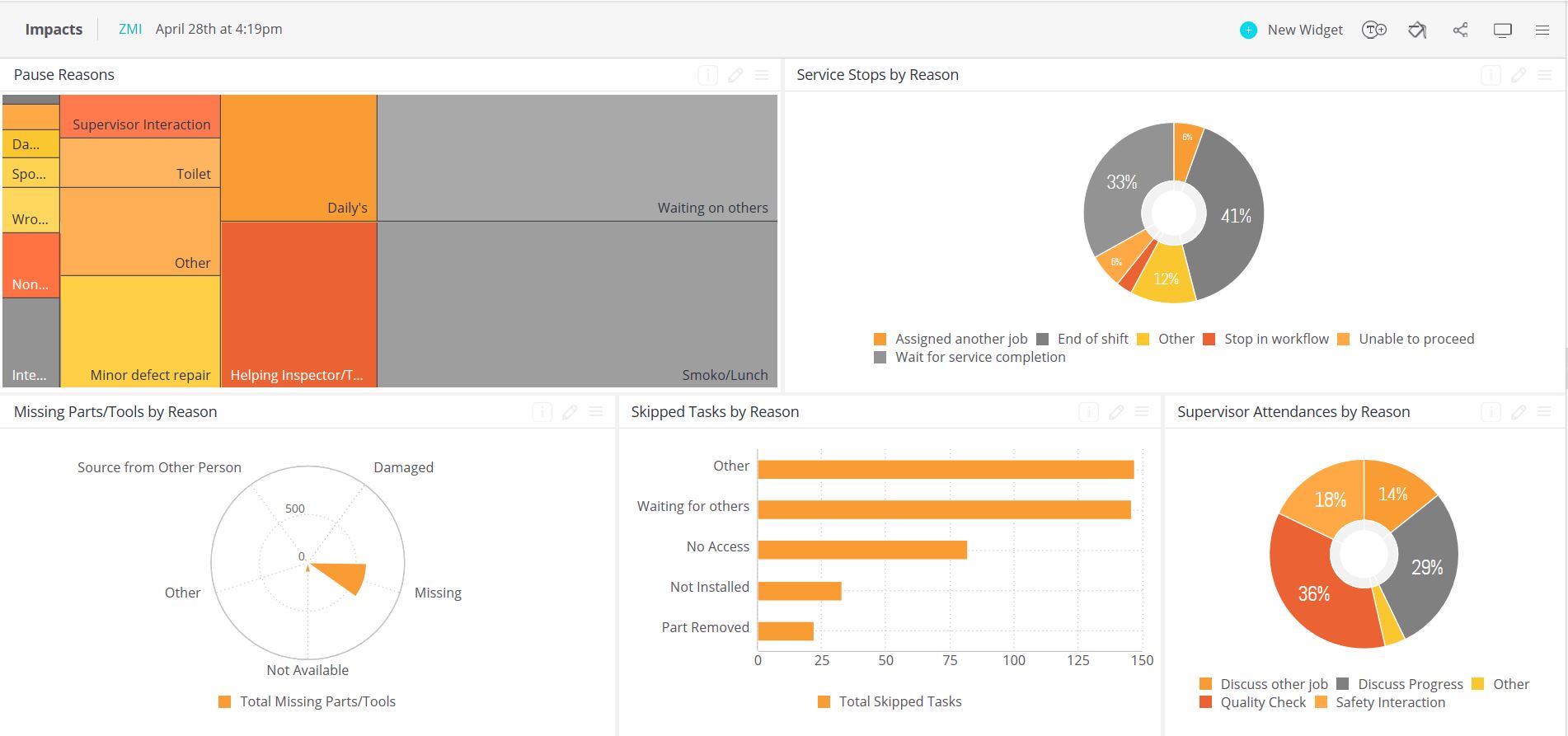

Even more importantly, over the last day, week, month, or year, management can see what caused delays and lost time on the job and what led to the most significant impacts on the maintenance department.

Wouldn’t you like an easier way to cut down the delays and downtime?

Get in touch today, and we'll show you how easily this can be achieved.

Pause timer

Select from reasons to pause

Results based over defined time frame

Web Based Dashboard option available